Understanding Injection Molding Companies

What is Injection Molding?

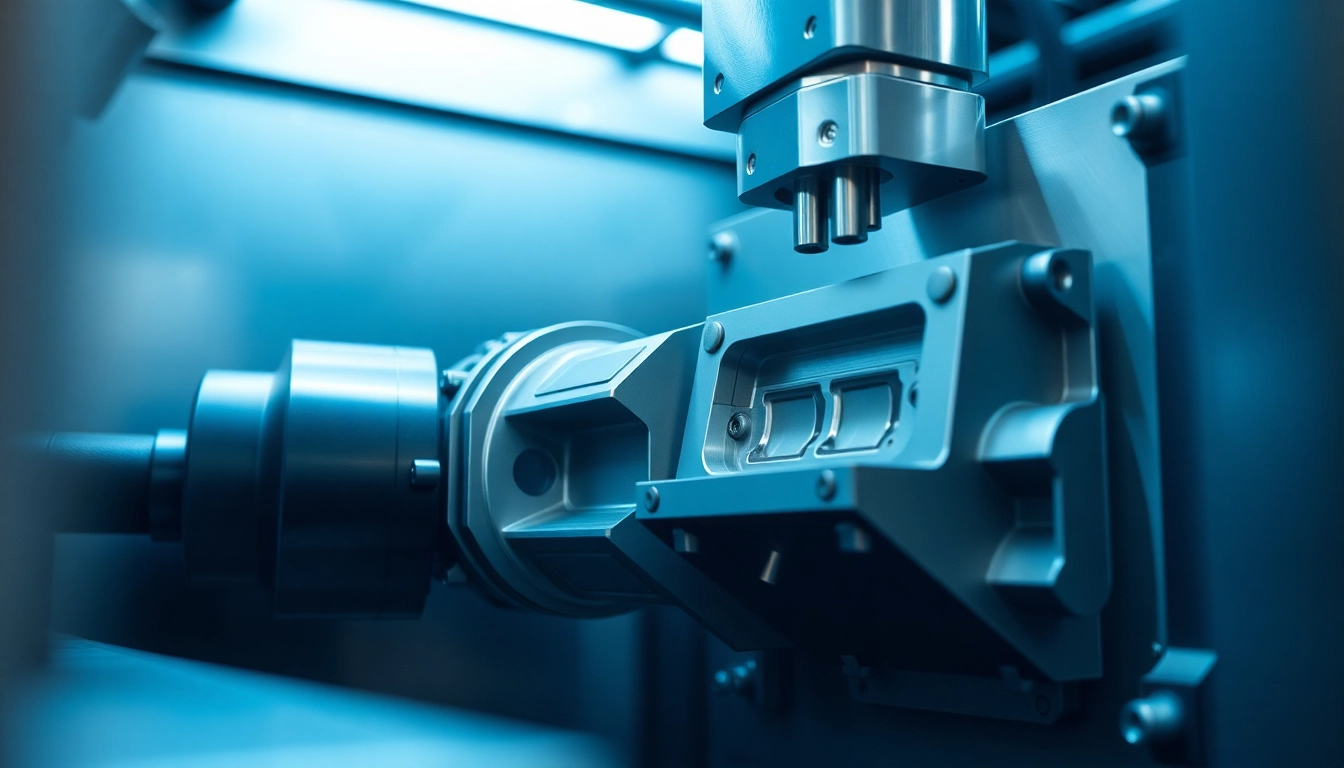

Injection molding is a manufacturing process used for producing large quantities of parts and products from various materials, primarily thermoplastic and thermosetting plastics. The method involves injecting molten material into a mold cavity where it cools and solidifies into the desired shape. This process allows manufacturers to create complex and highly detailed products while minimizing waste and maximizing efficiency.

How Injection Molding Works

The injection molding process begins with the preparation of raw materials, typically in pellet form. These pellets are fed into a heated barrel where they are melted and mixed. The molten plastic is then injected into a mold under high pressure. Once the material fills the mold, it is allowed to cool and harden into the final product. The entire process can take anywhere from a few seconds to several minutes, depending on the size and complexity of the part being produced.

The Role of Injection Molding Companies in Manufacturing

Injection molding companies play a crucial role in modern manufacturing by providing services that encompass everything from design and prototyping to bulk production and logistics. These companies work closely with clients to ensure specifications are met and products are delivered efficiently. A reputable injection molding company understands the intricacies of material selection, mold design, and production processes, ensuring high-quality output aligned with client needs.

Benefits of Partnering with an Injection Molding Company

Cost Efficiency and Production Speed

One of the primary advantages of collaborating with an injection molding company is cost efficiency. The initial setup cost for molds can be high, but when optimized for mass production, the cost per unit decreases significantly. Injection molding is capable of producing parts at a rapid rate, which can greatly reduce lead times. For industries such as automotive and consumer goods, where demand is high, this rapid production capacity translates to meeting deadlines and reducing inventory costs.

Quality Assurance and Consistency

Quality is paramount in manufacturing, and injection molding companies excel in producing parts that are consistent and meet stringent quality standards. Advanced technology, such as computer numerical control (CNC) for machining molds, and automated quality inspection systems, enables these companies to maintain high levels of precision. This minimizes errors and defects, which is crucial for sectors such as medical and aerospace, where product failure can have serious consequences.

Access to Advanced Technology

Injection molding companies are often equipped with the latest technology and machinery, which enables them to handle a wide range of materials and produce complex geometries. For example, advancements in 3D printing and rapid prototyping techniques allow companies to create prototypes quickly for testing before full-scale production. This access is beneficial for businesses that lack the capital to invest in such technologies on their own.

Key Factors to Consider When Choosing an Injection Molding Company

Experience and Industry Reputation

The first consideration when selecting an injection molding company should be their experience and reputation within the industry. A company with a proven track record and positive client testimonials will likely offer better quality and reliability. Additionally, industry certifications can indicate adherence to quality standards, which is vital for ensuring product compliance with regulations.

Manufacturing Capabilities and Technology

Understand the specific capabilities of an injection molding company, as this can affect the manufacturing process and final product. This includes looking at their machinery, mold design capabilities, and the range of materials they work with. Companies that embrace innovative technologies and methodologies—such as sustainable practices and automated production lines—can often deliver superior results.

Customer Support and Communication

Effective customer support and communication are essential for a successful partnership with an injection molding company. Choose a company that prioritizes client engagement, offering detailed project updates and quick responses to inquiries. This open line of communication can ease potential challenges during production and foster a collaborative working environment.

Common Challenges with Injection Molding Companies

Tackling Material Selection Issues

Material selection is crucial in injection molding as it directly affects the durability, functionality, and cost of the final product. With various options available, it can be challenging to choose the right one. Injection molding companies should provide guidance based on experience and market knowledge, helping businesses understand the trade-offs regarding materials, costs, and suitability for their specific applications.

Ensuring Prototyping Accuracy

Creating accurate prototypes is essential for validating designs before mass production. Challenges can arise from miscommunication or complications during the prototyping phase. A close collaboration with the injection molding company helps ensure prototype designs are captured accurately and adjustments can be made promptly to address any discrepancies.

Managing Production Lead Times

Production lead times can vary significantly based on the complexity of the molds, the materials, and the volume of production required. Anticipating delays and effectively managing timelines is essential to meet customer demands. Injection molding companies can assist by providing realistic timelines and maintaining open communication about potential setbacks due to external factors like material shortages or equipment failures.

Future Trends in Injection Molding Companies

Sustainability Practices in Manufacturing

Sustainability has become a focal point in manufacturing, including injection molding. Companies are increasingly seeking to use recycled materials and implement energy-efficient processes. Injection molding companies that adopt sustainable practices not only enhance their brand image but also appeal to environmentally conscious clients. This trend is driven by evolving regulations and consumer preferences for greener solutions.

Emerging Technologies in Injection Molding

The injection molding industry is witnessing significant technological advancements such as AI-driven automation, predictive maintenance, and digital twin technology. These innovations enhance production efficiency, reduce downtime, and enable real-time monitoring of processes. Injection molding companies adopting these technologies can offer increased reliability and improved product quality.

Market Demand and Industry Growth Forecasts

The global injection molding market is projected to continue its growth, influenced by trends in automotive production, consumer goods, and electronics manufacturing. Companies that proactively adapt to the growing demand for customized products and shorter lead times will thrive. Understanding market dynamics and consumer needs allows injection molding companies to position themselves strategically in the marketplace.